Harvest and Storage

Harvesting Grain Sorghum

Grain sorghum can be one of the more challenging grains to harvest. Time should be taken to properly adjust and operate the combine to achieve a harvest efficiency of 95% of the total grain.

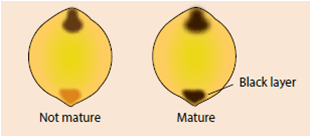

Grain sorghum can be harvested once the grain has reached physiological maturity and is no longer accumulating dry matter within the grain. Grain sorghum matures from the top of the head and progresses downward to the base. Considering this, it is important to check the grain at the bottom of the head to determine whether the grain is mature. Initially, hard starch accumulates at the top or crown of each kernel. The grain is considered mature once the hard starch has filled to the base of the kernel. Mature grain will be hard to penetrate when pinching the bottom of the kernel between your fingernails and should have a black spot at its base.

Grain sorghum is harvested with a combine using a grain header with a rigid cutter bar, a flex header in the rigid position or a row crop header. Guards that help pick up heads are recommended if heads are drooping or stalks are lodged. Sorghum stalks are generally much wetter than corn stalks at harvest, and they may be sticky from sugars. Stalk and green leaf material pulled into the harvester is more likely to clump in the combine, thus increasing harvest losses, and residue can also collect in the hopper with grain. Stalk material mixed in with grain can cause problems with drying and storing. To avoid these problems with standing sorghum, raise and lower the header as needed to harvest as little of the stalk and leaves as possible.

Producers may want to consider harvest aids to dry down the leaves and stalks for easier threshing or to dry out the late-emerging non-productive sucker-head tillers.

Moisture Content

At maturity, grain moisture is typically between 25-30%. Grain will often be discounted at the elevator if the moisture content is above 14% due to the cost of drying the grain. For this reason, growers often wait for the grain to naturally dry down in the field or will apply a harvest aid to speed up the process. When drying conditions are favorable i.e., temperatures greater than 75 F, breezy, low humidity, grain may lose 1% moisture per day. In many of the humid areas where sorghum is grown, growers will often elect to harvest the grain between 17-20% moisture. This tends to result in a higher quality grain, although it must be dried prior to storage.

Minimizing Harvest Loss

- Preharvest loss is typically weather related and can be minimized by timely harvesting. Crops left in the field too long can be damaged by birds or field shatter. Severe weather before or during harvest can cause lodging, which makes the crop difficult to harvest. Combine size, crop acreage and available work days dictate timeliness.

- Header loss includes shattered kernels, dropped heads and uncut heads. If a conventional reel is used, the speed of the reel bats should be slightly faster than ground speed. Operating the reel too fast will increase shatter losses while operating too slow will cause dropped heads. Several attachments are available to improve gathering efficiency. Flexible guard extensions on grain platforms substantially reduce gathering losses in standing-crop conditions. Row attachments on grain platforms or using a row-crop head reduces losses in both standing and lodged conditions.

- Cylinder loss or unthreshed grain can be a major problem with grain sorghum. It is often necessary to compromise between adequate threshing and excessive kernel cracking. Cracking can be caused by either too little clearance or a too rapid cylinder speed, but speed is usually the cause. Severe threshing action can pulverize the stalks and overload the cleaning shoe and walker. It is often necessary to leave up to 2% of the grain in the head to achieve the best overall harvesting results. In high-moisture grain sorghum, cylinder speed and concave-clearance adjustments are critical. As the head passes through the cylinder area, rolling it, rather than a shearing, provides maximum threshing with minimum kernel and stalk damage. The cylinder-concave clearance should be set so the stalks are not crushed, and cylinder speed should be increased until thorough threshing occurs. This often requires wider cylinder-concave clearance than harvesting sorghum at lower moisture contents.

- Shoe loss is grain carried or blown across the shoe. Kansas State University research indicates it may be the most serious and most overlooked source of harvesting loss in grain sorghum. In most modern combines, the shoe and not the cylinder is the first component of the combine to overload in grain sorghum. If the combine operator pushes the machine as fast as the cylinder can go, the shoe is usually losing large quantities of grain. In one series of tests, a 33% increase in ground speed caused shoe loss to increase by more than 4% of the total yield. Shoe losses also are increased when operating on hillsides. The amount of air blown on the shoe is important, as is the opening of the louvers. Closing the chaffer louvers will increase the air velocity through the opening. Air opening or fan speed should be reduced as the louver opening is closed.

- Walker loss can be caused by excessive speed also, but, in most combines the walkers’ overload after the shoe. Therefore, walker overloading is of secondary importance when combining grain sorghum.

Drying

Producers should be extremely cautious in holding high-moisture grain sorghum prior to drying. High-moisture grain sorghum packs much tighter than high-moisture corn. This inhibits air circulation within the grain and can result in heating, molding and sprouting problems. Never hold wet sorghum longer than 2-4 hours unless aeration is provided.

Continuous flow or batch dryers are the preferred methods for drying grain sorghum. If it must be dried in a bin, the bin should be used as a batch-in bin dryer, limiting the drying depth of each batch to 4 feet. After drying, cool the grain and move it to another storage bin before the next day’s harvest. A 3-foot depth of sorghum is equivalent in resistance to a 4-foot depth of corn at an airflow rate of 10 cfm. An individual seed of grain sorghum will dry faster than an individual seed of corn, but greater flow resistance from a bin of sorghum will reduce the airflow. As a result, the drying time for grain sorghum is longer than for corn. Cooling time is also longer.

Optimum drying temperature depends on the type of dryer, airflow rate, end use i.e., feed, market, seed, and initial and final moisture contents. The maximum temperature for drying grain sorghum for use as seed should not exceed 110 F. Dry for milling below 140 F in high airflow batch and continuous flow dryers and 120 F in bin dryers. If used for feed, drying temperatures can be up to 180 F. Always cool grain to within 5-10 degrees of the average outside air temperature after drying. Natural, unheated air may be used when the relative humidity is 55% or less and the grain moisture is 15% or less.

Natural, unheated air drying can be used to dry grain sorghum if the moisture content is 16% or below and the drying depth is less than 10 feet. Drying fans must be capable of delivering at least 1-2 cfm/bushel. Because the drying process is slow, it is important to start the fans immediately after the floor is covered.

Storing Grain Sorghum

Aeration is one of the most important management tools available to producers for maintaining grain quality in sorghum storage. Aeration extends the storage life of grain by removing odors, preventing moisture accumulation and controlling conditions conducive to mold growth and insect activity.

Grain should be aerated after it is dried and in the fall, winter and spring. Begin aeration when the average outdoor temperature is 10-15°F lower than the grain temperature. Average outside temperature can be taken as the average of the high and low temperatures over a 3-5 day period. Check grain temperatures at various locations in the bin with a probe and thermometer.

Inspect all grain in storage at least once a week. Check for indications of moisture such as crusting or condensation on the bin roof. Check and record the temperature at several points in the stored grain. Any increase in temperature indicates a problem unless outside temperatures are warmer than the grain. Probe the grain to check for insects or other problems. If problems are noticed, run the aeration fans.